PRODUCTION PROCESSES

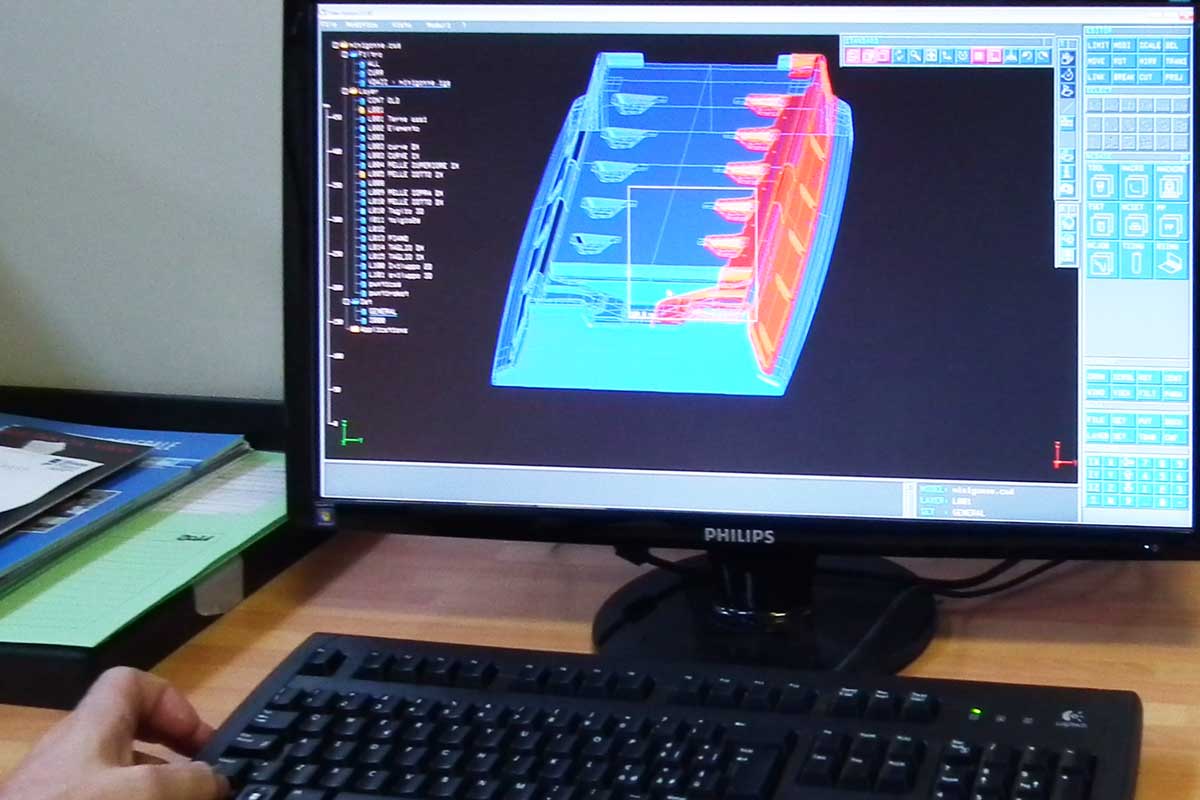

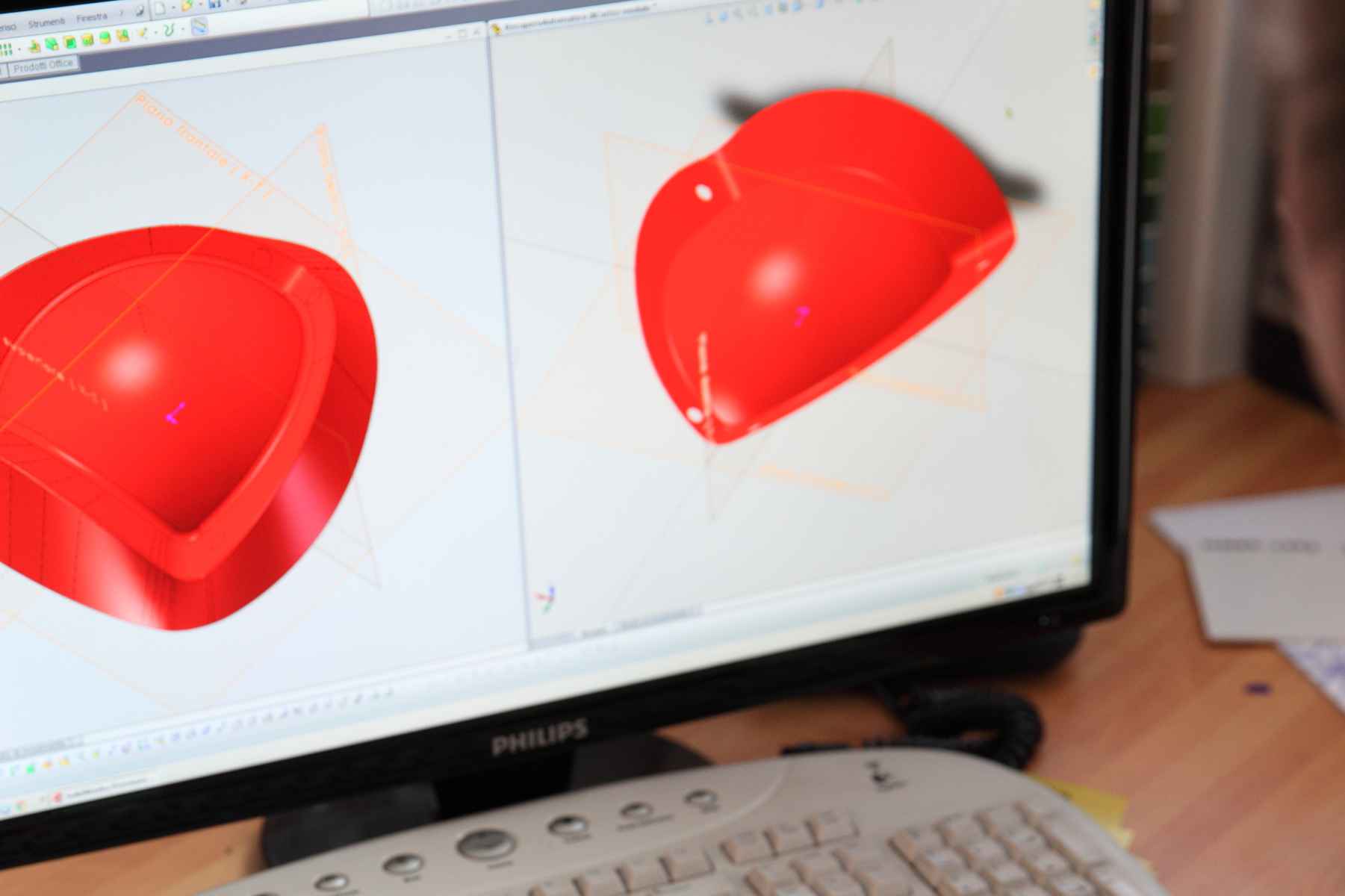

Technical Department

Our technical department is able to create, modify and prepare any type of project. We use Rhinoceros CAD/CAM software for technical drafting and modelling.

The use of these application solutions allows us to building quickly and precisely from the drawing to the production equipment, and makes a very high execution accuracy possible.

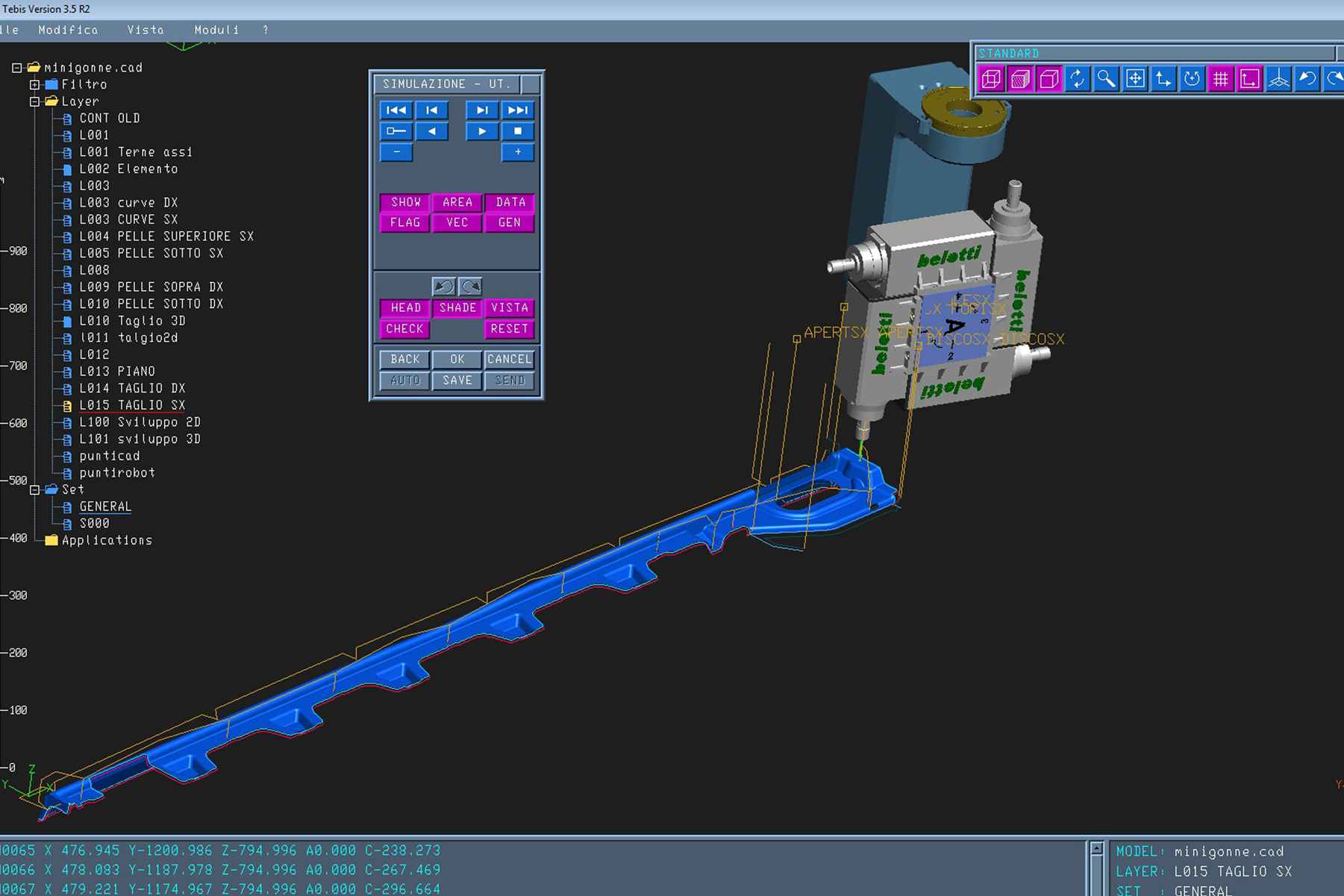

Robotic cutting

This process allows complex and structured actions to be performed, such as working on irregular surfaces. CAD/CAM 3D graphic programs entirely interfaced with an internal data communication network are used in the robotic cutting operations.

Foaming

Our foaming department is able to cover the dimensional requirements (3000×1500 mm h 1000) arising from the production cycle of the thermoforming and cutting departments.

The materials used comply with the national and international regulations – UNI EN ISO, ASTM, DIN, BS. The polyhydric alcohol and isocynanide mixture is blended at high or low density, depending on the sector in which the foaming will be applied (e.g. refrigeration, furnishings or sanitary fixtures).

Digital printing, silkscreen printing, lacquering

Isolplastic is able to help you in choosing the technology best suited to the graphic customization to be applied to the final product.

Processes such as digital or silkscreen printing are highly demanded in the field of visual communication and advertising (e.g. panels and signs for stores, showcases, commercial activities), one of the fields in which we are specialised.

Gluing and assembly

If after the cutting phase the product requires any subsequent processes, Isolplastic has a well-tested and fully equipped department for ultrasonic welding, assembly and various gluing techniques.